How to Reduce the Cost of Product Packaging

Keeping costs low is an integral part of any business plan. But reducing the cost of your product packaging does not mean cutting corners or producing cheap merchandise.

With a bit of expert help, you can pare unnecessary expenses and simultaneously give the impression of a high-end product.

A few simple rules of economics apply to packaging. Buy in bulk to cut down on the price-per-item. Utilize competent in-house design and rely on overseas manufacturing to save money. Minimize the weight of your packaging to lower delivery costs and get more bang for your buck. When you do your homework and choose lightweight, durable materials, your cost reduction will pay dividends and allow you to invest in other areas of your business.

Even “luxury” packaging is surprisingly affordable if you follow a few common-sense guidelines. Not only will you streamline your manufacturing process, but you will also boost sales as customers respond to your new brand image.

Buy Packing in High-Volume Orders

Design represents a considerable percentage of the total cost of packaging. Printers have numerous “fixed costs” like color and glue, which are built into the final price. These frequently cost many thousands of dollars and ultimately leave your clients with the bill.

By spreading these fixed costs over many items in a high volume order, the cost-per-item will plummet. Although you’ll pay more in total, your business can save thousands of dollars and avoid the hassle of re-ordering more packaging and packaging materials.

Consider Your Packaging Materials

Size and weight are vitally important to the final cost of your product packaging. For instance, rigid luxury boxes cannot be folded during delivery, dramatically increasing their shipping price.

Some packaging and printing companies may try to upcharge for multi-color inks, matte finish, custom decals, or UV protection. While these add-ons can be appropriate in some situations, you’ll need to determine if they are suitable for your product.

Even the reduction of a few cents per box will add up at scale. Avoid unnecessary upcharges and save money on both materials and labor. Another way to cut costs is to think about outsourcing your packaging manufacture overseas.

Consider Outsourcing Your Packaging Manufacture

Many businesses prefer to design their products in the United States and find cheaper international manufacturing options. Because of discrepancies in labor prices, you can get an identical product for a fraction of the price.

Benefit from the high-quality design of a domestic company and enjoy the ease of communicating in the same time zone and paying in U.S. dollars. Most qualified packaging companies have strong working relationships with a variety of overseas manufacturers. However, you’ll want to bear in mind the logistical ramifications of working with an overseas manufacturer, particularly since the pandemic has impacted ocean and air freight.

Optimize Sales with Speed to Marker

As COVID-19 complicates ocean freight worldwide, it’s crucial to stay one step ahead of the competition. For instance, if you need your product on shelves before the holiday season, delays in ocean freight might prevent your packaging from arriving for many months.

To avoid paying extra for expensive air-freight, plan your merchandising and packaging several quarters in advance. Avoid “just in time” deliveries and guarantee your products will hit shelves with time to spare.

Enlist Companies that Specialize in Custom Packaging

Many packaging companies are designed to deal with generic orders and standardized packaging. A custom packaging company can match your exact needs, create an unforgettable design, and save money in the process.

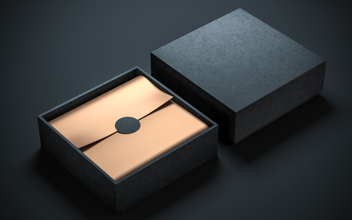

Add custom logos to your packaging, emboss eye-catching designs, and reduce shipping costs by minimizing excess weight. An agile custom packaging company can mock up several prototypes and ensure everyone is happy with the final product.

RELATED CONTENT: 4 Mistakes to Avoid with Custom Luxury Gift Boxes

Bundle Your Manufacturing and Logistics

Experienced product packaging companies usually have warehouse infrastructure and sophisticated logistics systems to streamline their manufacturing process. Focus on your core business and leave the complicated planning to professionals.

Compare prices and get a discount when you bundle services. Companies like Global Printing & Packaging have years of experience shipping products around the world.

The vast majority of businesses don’t have in-house logistics departments. Save yourself the trouble of hiring new employees and depend on efficient and affordable operations without sacrificing quality.

There is no perfect formula for saving money on product packaging. But with a few helpful guidelines, you are virtually guaranteed to reduce costs. The most crucial step is choosing a qualified packaging company with a wide variety of flexible packaging options.