What Are Custom Rigid Boxes & What Are the Benefits?

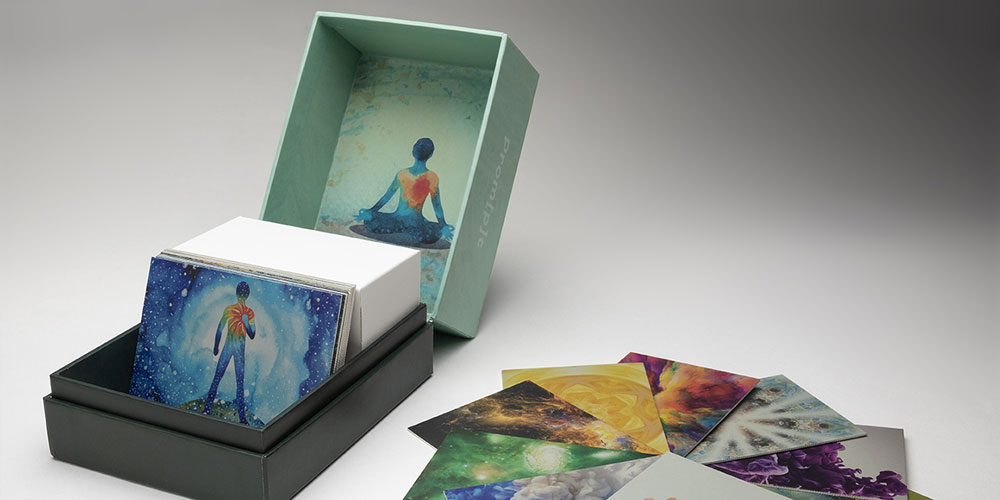

Custom rigid boxes are a premium packaging solution known for their strength, durability, and high-end appeal.

Unlike standard packaging, these boxes are made from sturdier materials and are not collapsible, offering superior protection and a luxurious unboxing experience.

Tailored to specific dimensions and design preferences, they effectively enhance brand value and make a lasting impression on consumers. The benefits of custom rigid boxes are extensive and significant, especially for businesses looking to elevate their product presentation and create a memorable customer experience.

- Enhanced Product Protection: Their sturdy construction provides excellent protection for the contents, reducing the risk of damage during shipping and handling.

- Elevated Brand Perception: Custom rigid boxes’ high-quality look and feel can significantly elevate a brand’s perceived value and prestige.

- Customizable Design: They offer vast customization options, including size, shape, color, printing, and finishes, allowing for a unique brand presentation.

- Sustainability Options: Many rigid boxes can be made from sustainable materials, offering eco-friendly packaging that resonates with environmentally conscious consumers.

- Improved Customer Experience: The unboxing experience with a custom rigid box can be memorable and engaging, fostering customer loyalty and repeat purchases.

- Marketing and Branding Tool: Beyond packaging, these boxes are powerful marketing tools, enhancing brand recognition and visibility.

- Versatility: Suitable for a wide range of products, from luxury goods to electronics, they can be designed to fit specific product needs and aesthetics.

Short on time? Download the guide and read it later.

Types of Rigid Boxes

Rigid boxes come in various styles and designs, each offering a unique appeal and functionality. These boxes are more than just a means to present a product; they are an extension of the brand and an integral part of the customer experience.

Whether you’re packaging high-end retail items, exclusive corporate gifts, or personal keepsakes, understanding the different types of boxes is important for selecting the perfect packaging solution that resonates with your brand and delights your customers.

- Magnetic Closure Boxes: These boxes feature a magnetic lid that snaps shut, providing a sleek and secure closure. Ideal for a premium and modern unboxing experience.

- Hinged Lid Boxes: Classic and elegant, these boxes have a lid attached to the base, creating a seamless opening experience. Perfect for showcasing high-value products.

- Sliding Drawer Boxes: Offering a unique unboxing experience, these boxes include a drawer that slides out, adding an element of surprise and interaction.

- Collapsible Rigid Boxes: Designed for convenience and efficiency, these boxes can be flattened for easy storage and transportation and reassembled when needed.

- Round Rigid Boxes: A unique variation, round boxes stand out for their shape and are often used for specialty products or decorative keepsake boxes.

- Two-Piece Rigid Boxes: Consisting of a separate lid and base, this classic box style offers a timeless and versatile packaging solution.

- Windowed Rigid Boxes: A transparent window allows a sneak peek at the product inside, adding to the anticipation and visual appeal.

- Custom-Shaped Rigid Boxes: Tailored to fit unique product shapes or themes, these boxes are perfect for creating a distinctive and memorable packaging experience.

- Rigid Sleeve Boxes: These boxes consist of a sleeve that slides over a tray or base, combining simplicity with elegance and ease of use.

- Book Style Boxes: Mimicking the look of a book, these boxes open to reveal the product inside, offering a sophisticated and literary twist to packaging.

What Are the Best Materials for Rigid Box Packaging?

The choice of material for your rigid box packaging plays a pivotal role in its appearance and functionality. Popular materials include:

- High-Density Fiberboard: Known for its strength and durability

- Art Paper: Offers a smooth surface ideal for printing

- Kraft Paper: Eco-friendly and sturdy

- Specialty Papers: Such as textured or metallic finishes for a unique touch

When selecting materials, consider sustainability, durability, and how well it will convey your brand’s message.

Understanding Your Packaging Design Options

Packaging design options for rigid boxes are vast, ranging from various printing techniques like offset or digital printing to different finishes such as matte, gloss, or UV coating. You can also add embellishments like foil stamping and embossing for a more luxurious feel. The design process involves:

-

Conceptualization: Brainstorming design ideas that align with your brand identity

-

Prototyping: Creating a mock-up for visual and tactile evaluation.

-

Production: Finalize the design and move forward with mass production.

What Does Rigid Box Packaging Cost?

Rigid boxes are a premium packaging solution for luxury products or high-end branding, and the cost depends on several factors.

Packaging durability, material quality, and customization options all play a role in what you will spend. Still, other cost-related factors exist that companies often don’t consider, like transportation and inventory management.

Domestic packaging companies charge more per unit but often can turn around orders faster than other providers.

Packaging companies with overseas manufacturing operations, on the other hand, offer a lower cost per unit on bulk orders, and some of them can also turn around orders quickly. They can also help you reduce costs by optimizing your shipments.

Some providers use 3D modeling to find significant cost savings per truckload or container-load by adjusting the dimensions of your packaging. Reducing the box size by as little as one inch sometimes has a big impact on the cost.

Packaging companies that maintain their supply chains can also improve your bottom line with “just in time inventory.” By ordering your packaging months in advance and managing the inventory in a warehouse, you can achieve greater discounts on bulk orders and ensure you don’t run out of packaging at critical times. Packaging providers that own warehouses and supply chains can always find efficiencies throughout the process to reduce costs.

Factors that impact cost:

- Material Quality: Higher quality materials such as thick paperboard or specialty finishes will increase the cost.

- Size and Complexity: Larger boxes or designs with intricate shapes and details are more expensive to produce.

- Quantity: Ordering in bulk typically reduces the cost per unit, offering economies of scale.

- Customization and Printing: Custom designs, unique shapes, and high-quality printing techniques add to the cost.

- Additional Features: Extras like magnetic closures, foam inserts, or specialty coatings will also contribute to the price.

- Shipping/Supply Chain: Depending on the size of the order and the shipping distance, these costs can add up.

Here’s a general breakdown of what you might expect to pay for rigid boxes without factoring in bulk order discounts or logistics-related savings:

- Small Boxes (like for jewelry): $1 - $5 per box

- Medium Boxes (like for electronics): $3 - $10 per box

- Large Boxes (like for board games): $5 - $20 per box

How to Optimize Your Packaging Inventory

Optimizing your packaging inventory, especially when dealing with premium options like rigid box packaging, is crucial for maintaining cost-effectiveness and operational efficiency. Effective inventory management ensures enough packaging to meet demand without overstocking, which can tie up capital and storage space.

It involves a strategic approach that balances demand forecasting, storage practices, and supplier relationships. Here are some key strategies to optimize your rigid box packaging inventory:

- Accurate Demand Forecasting: Use sales data and market trends to predict future packaging needs, avoiding shortages and excess inventory.

- Just-in-Time Ordering: Implement a just-in-time inventory system to order packaging materials as needed, reducing storage costs and the risk of obsolescence.

- Supplier Relationships: Develop strong relationships with packaging suppliers to ensure reliable lead times and the flexibility to accommodate urgent orders.

- Storage Solutions: Invest in efficient storage solutions that maximize space and preserve the quality of the packaging.

- Bulk Purchasing vs. Small Orders: Assess the pros and cons of bulk purchasing against smaller, more frequent orders based on storage capacity and cash flow.

- Consider Seasonal Variations: Plan for seasonal peak and product demand troughs, adjusting inventory levels accordingly.

- Sustainability Practices: Incorporate sustainable practices by reusing or recycling

What to Look for in a Rigid Box Manufacturer

Choosing the right rigid box manufacturer ensures the final product aligns with your brand’s quality and aesthetic standards. High-end products demand packaging that reflects their value and appeals to discerning customers.

When evaluating manufacturers for rigid boxes, it’s important to consider several key factors contributing to the packaging quality, reliability, and overall appeal. Here are some essential aspects to keep in mind:

- Quality of Materials: Look for manufacturers that use premium materials, which not only enhance the look and feel of the box but also ensure durability.

- Customization Capabilities: Customizing aspects like size, shape, color, and finishes is essential for creating unique packaging that stands out.

- Printing and Finishing Techniques: Advanced printing techniques (such as foil stamping, embossing, UV coating) and high-quality finishes can significantly elevate the box’s appearance.

- Attention to Detail: Precision in construction and detailing, like seamless corners and perfect alignments, are indicators of high craftsmanship.

- Sustainability Practices: Manufacturers who offer eco-friendly options and sustainable practices can help align your packaging with environmental values.

- Production Lead Time: Consider their ability to meet your timelines, especially if you require packaging for a specific event or launch.

- Portfolio and Past Work: Review their portfolio to assess their experience and expertise in creating luxury packaging solutions.

- Customer Service and Communication: Responsive customer service and clear communication are vital for a smooth production process and timely delivery.

- Cost-Effectiveness: While luxury packaging demands a higher investment, the manufacturer should still offer competitive pricing and value for money.

Conclusion

Rigid box packaging, with its blend of durability, elegance, and customization, offers a unique opportunity to make a lasting impression on your customers. From the enhanced protection they provide to your products to the elevated brand perception they create, these boxes are an investment in your brand’s image and customer experience.

Whether you’re a small business just starting out or an established brand looking to upgrade your packaging, understanding the nuances of rigid box packaging is critical. Remember to consider factors like material quality, design options, cost, inventory management, and the choice of manufacturer carefully.

Doing so ensures that your packaging protects and presents your products in the best possible light, aligns with your brand’s values, and appeals to your target audience. In the world of product presentation, custom rigid box packaging stands out as a premium choice that can significantly contribute to the success and perception of your brand..